Bangalore Waste to Energy Integrated Waste Management Project: Update 2

Last week, the Bangalore International Airport Ltd team dropped into our plant to celebrate the start of something new by hosting a small Puja. An

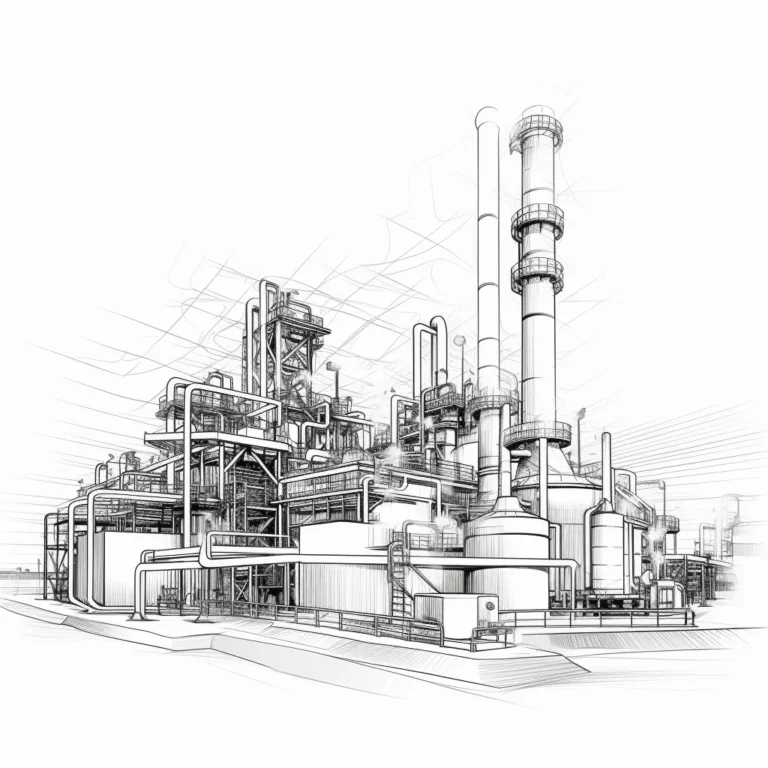

The project involves the establishment of a 300 KLPD agri-waste-based distillery to supply bio-ethanol to Oil & Marketing Companies (OMC's) adhering to E-20 standards. An investor has partnered with a specialized entity for this endeavor. The project aims to meet the increasing demand for bioethanol as mandated by the government's biofuel blend targets. Agreements have been secured with government companies and a reputable private entity to ensure off-take of the produced bio-ethanol.

Bioethanol production involves a multi-step process starting with the selection of feedstock, such as agricultural crops or cellulose-rich materials. The feedstock undergoes pretreatment to prepare it for further processing. Enzymatic hydrolysis breaks down complex carbohydrates into fermentable sugars. Fermentation occurs with the addition of yeast, converting sugars into ethanol. Distillation is employed to separate ethanol from water, followed by dehydration to remove any remaining water. Rectification may be performed to further purify the ethanol. Finally, blending takes place, where ethanol is mixed with conventional gasoline or diesel fuel to create biofuel blends. Quality control measures ensure the ethanol meets required specifications. Ongoing research explores advancements to enhance the efficiency and sustainability of bioethanol production.

The market opportunity for this project lies in the growing demand for bioethanol as a result of the government's biofuel blend targets. With gasoline demand projected to increase, there is a significant need for a larger supply of ethanol for blending. By establishing a 300 KLPD agri-waste-based distillery to produce bioethanol, the project can tap into this opportunity and cater to the requirements of Oil & Marketing Companies (OMC's) seeking to blend ethanol with petrol.

The project aims to capitalize on the projected demand and contribute to bridging the demand and supply gap, while also benefiting from the fixed "refinery" margin price mechanism based on fluctuating feedstock costs.

The project opportunity lies in establishing a bioethanol production facility using agri-waste as feedstock. With increasing global demand for renewable fuels, bioethanol presents a promising solution. The project aims to leverage the growing demand for biofuels, driven by environmental regulations and the desire to reduce reliance on fossil fuels. By implementing an efficient manufacturing process and adhering to quality standards, the project can tap into the market potential and contribute to sustainable energy production.

The use of agri-waste as feedstock not only provides an environmentally friendly solution to waste management but also ensures a reliable and cost-effective supply. Overall, the project opportunity lies in meeting the market demand for bioethanol while promoting environmental sustainability and resource efficiency.

The feedstock for Bio-Ethanol production is "Broken Rice," readily available in rice-growing states and neighboring regions, despite being discarded due to contaminants. The presence of numerous FCI depots in the area offers easy access to surplus grains for ethanol production.

Last week, the Bangalore International Airport Ltd team dropped into our plant to celebrate the start of something new by hosting a small Puja. An

Here’s an update from our project site in Bengaluru. Our state-of-the-art biogas plant is one step closer to being completed. Our sorting lines are set,

Update Time : As we come one step closer to putting together the final touches on our Biogas plant, here’s a few behind the scenes

As the year comes to an end, we would like to update you one last time (for the year) on our Plant with a small

Please be informed that a substantial amount of information pertaining to this project is considered highly confidential. If you are interested in obtaining further details, we kindly request you to contact us at Info@nexusnovus.com for access.

Last week, the Bangalore International Airport Ltd team dropped into our plant to celebrate the start of something new by hosting a small Puja. An

Here’s an update from our project site in Bengaluru. Our state-of-the-art biogas plant is one step closer to being completed. Our sorting lines are set,

Update Time : As we come one step closer to putting together the final touches on our Biogas plant, here’s a few behind the scenes

As the year comes to an end, we would like to update you one last time (for the year) on our Plant with a small

Contact Us

If you are interested in obtaining further details, we kindly request you to contact us through form below

Bangalore, India

Sy No 38, Banglore Aerospace Park Near Kempagowda International Airport Devanahalli, Bangalore (Rural), Karnataka 562110

De Corridor 14J Breukelen 3621 ZB Netherland

SA80 Strand St, Cape Town City Centre, Cape Town, 8001, South Africa

NexusNovus Copyright © 2023 All Rights Reserved.